Every day, manufacturing facilities are challenged to increase capacity, improve delivery time, reduce risks, and streamline regulatory compliance. Every day, RedViking helps our customers meet those challenges. Whether you are early in the process, struggling to get your Industry 4.0 initiative started, or you have a strategy defined and need an implementation plan, RedViking is here to help. Our operational intelligence group helps customers realize tangible return on investment by analyzing, identifying, and implementing a strategy that uses real-time data to boost efficiency.

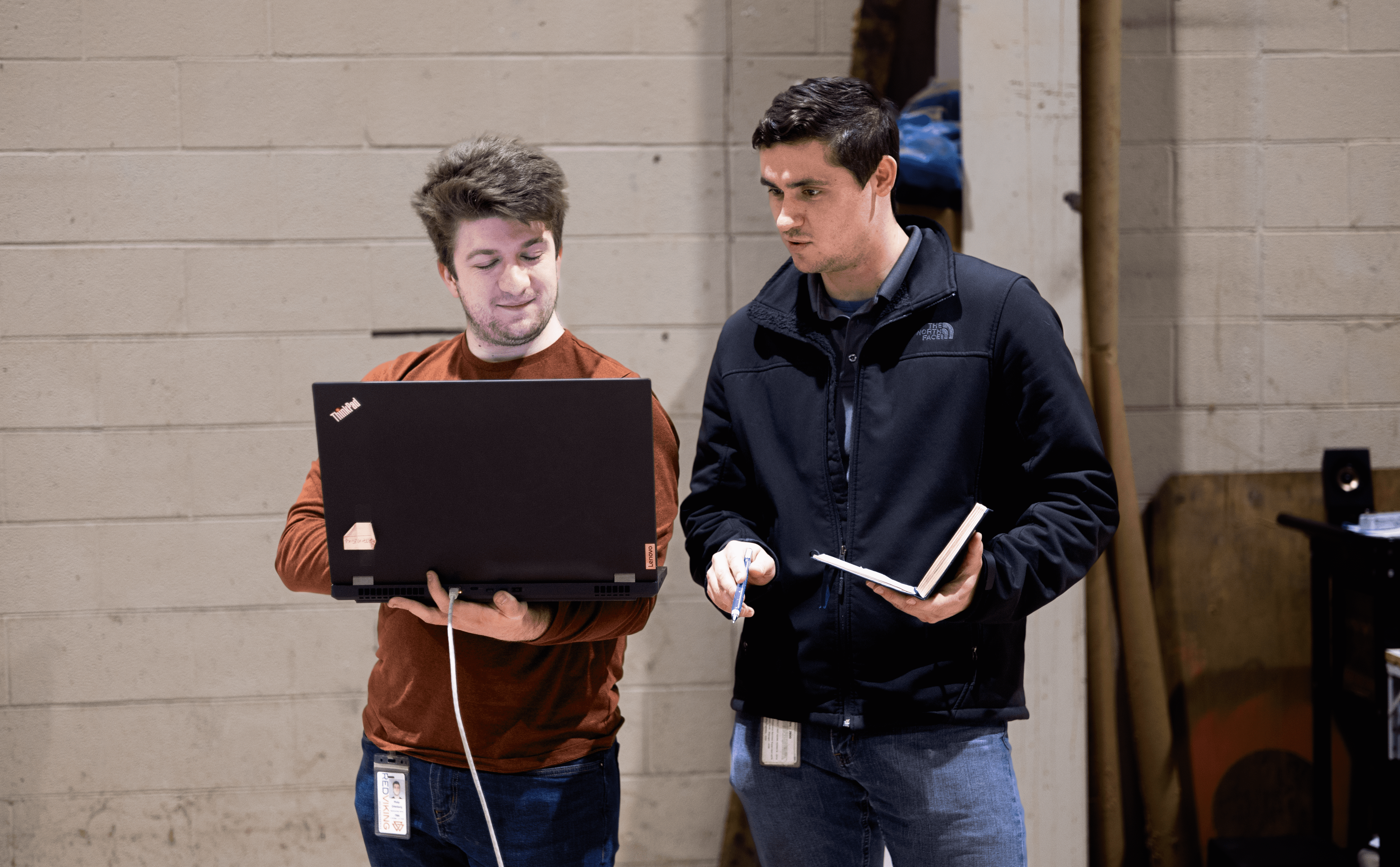

RedViking can help you evaluate and analyze your current information strategy, processes, challenges, and goals. Our team, in collaboration with your team, takes the time to study the logistics of your current process to understand the constraints and requirements of your product, facility, and information system. By obtaining these data points, we can design a operational intelligence solution that prioritizes your goals.

RedViking’s best-in-class practices help our customers avoid common pitfalls that can derail your information system. By thoroughly analyzing your process, product, and facility, RedViking can tailor the solution specifically to your needs. Whether we are dealing with your home-grown legacy software, a COTS MES system, or even designing custom manufacturing software, RedViking has a proven track record of engineering a solution and successfully deploying it for small and large global companies. We design and deliver a solution that meets your core goals without any guesswork.

RedViking has the practical experience to understand the impact of our manufacturing execution proposals because we have over thirty years of experience with manufacturing systems integration. We do not recommend a process without fully understanding its implementation. We have experience in technical specification development as well as standard hardware and software development. Our dedicated team of multidisciplinary professionals is ready to design, integrate, and support your manufacturing software needs – anywhere in the world.

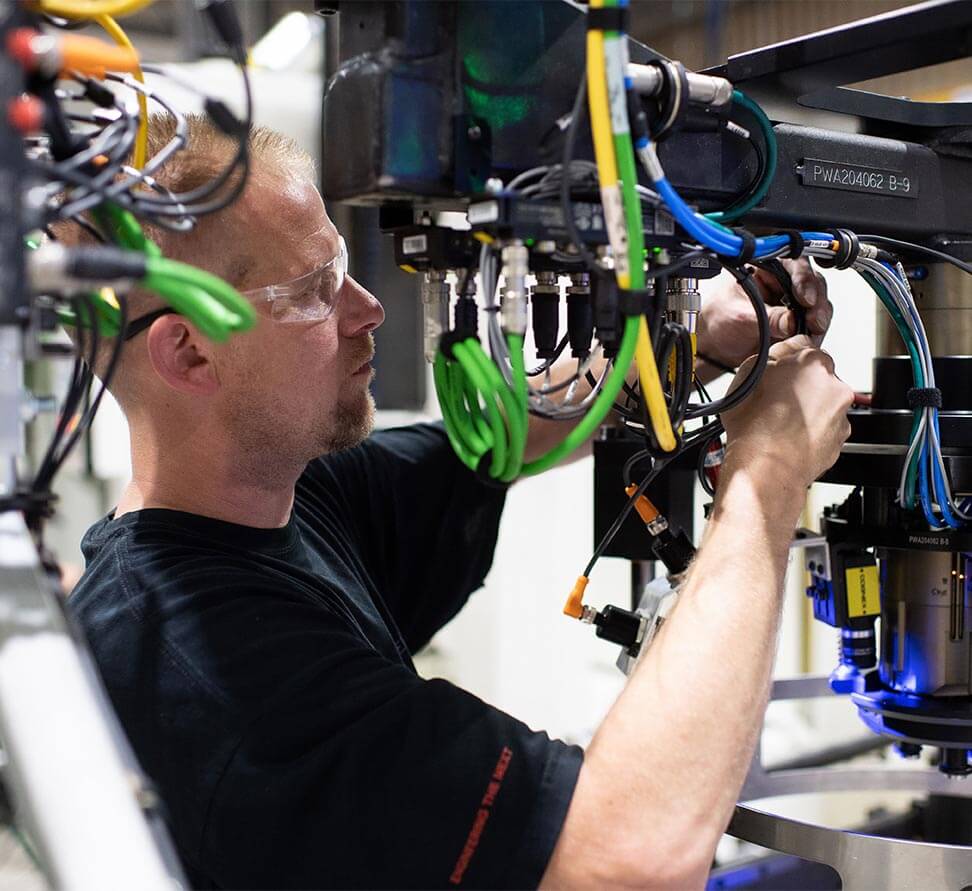

Customers have turned to RedViking for years because we have in-house controls design, engineering, and build capabilities. RedViking has the capability in-house to quickly design, procure, and build standardized elements of any system integration from operator stations to pick lights to power distribution and control systems. Our design and build shop can provide you with this standardized hardware, whether you need standard, off-the-shelf, elements, or custom elements.

Empower your production with our visionary automation solutions. Secure your place in the automated future – contact us to discuss your custom solution.