With lower energy costs available, are manufacturers still pursuing energy efficiency? The following is an excerpt from an article in Control Design. You can find the entire article by Dave Perkon here. Energy costs were low in 2016, which put the brakes on many energy-related projects. While energy efficiency may not be the hot topic it was a few years ago, machine builders continue to improve it because it can optimize the machines for more productive operation. Although sustainability doesn’t have the buzz it had a few years ago, corporations commonly mandate plant management with reducing the environmental footprint, as well as production costs.

Optimization and reliability

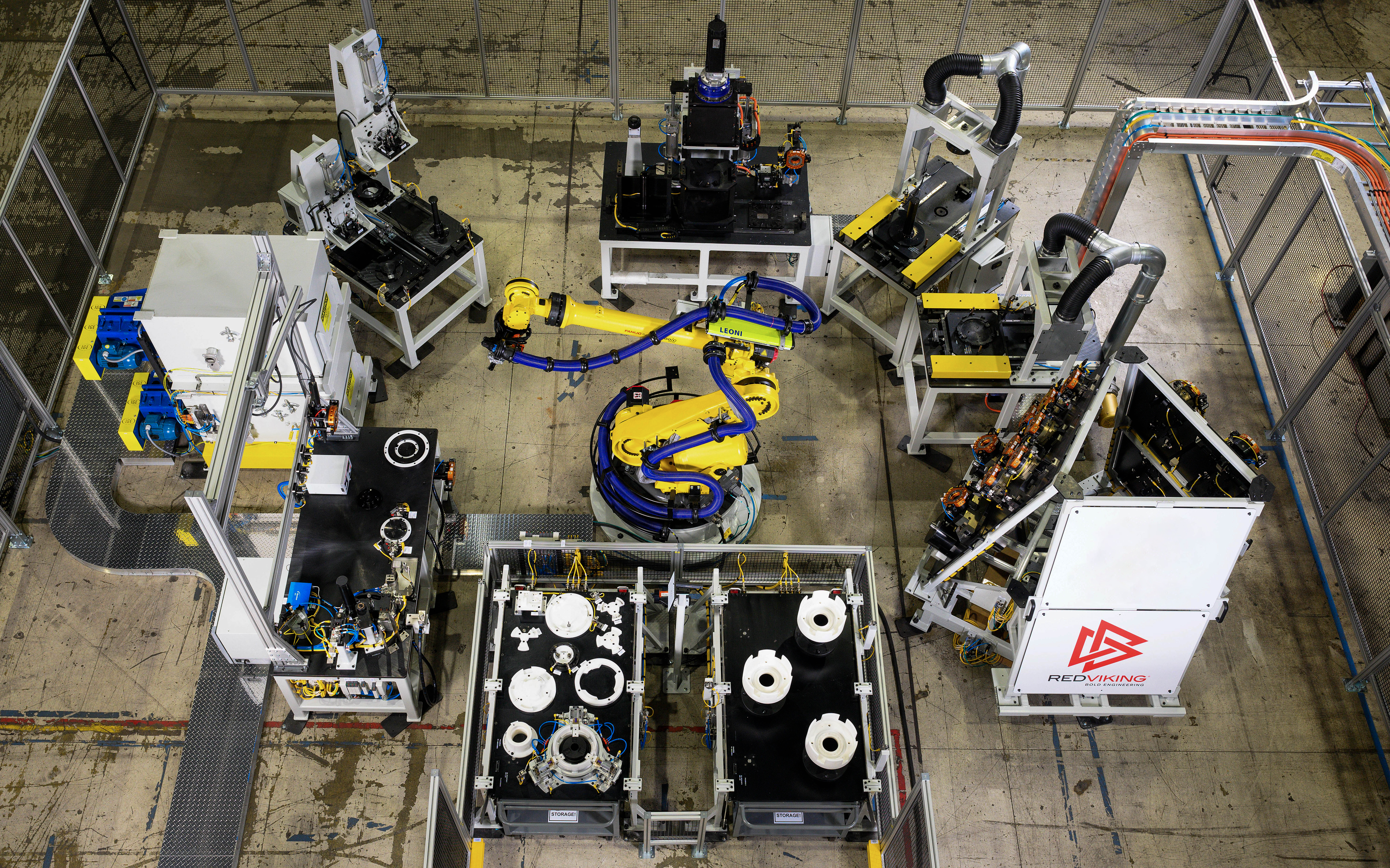

“The end user is looking for energy-efficient machines, but these users are also looking to do more work with fewer machines as a means of saving energy,” says Mark Sobkow, vice president of manufacturing solutions. “We do a lot of projects that focus on adding flexibility so that one machine or cell can do the work of what was done by many machines or cells in the past. That might take the form of a multi-attribute inspection machine or incorporating onboard automation onto assembly-line AGVs by using inductive power transfer (Figure 1). These allow plants to do more work with fewer machines.” It goes beyond more efficient use of machines, as well. “Plant managers’ responsibilities on energy efficiency extend into finding genuinely sustainable options,” says Sobkow. “As a result, we’re seeing demand increase significantly for battery-free assembly-line AGVs, since lithium ion and lead acid batteries are so potentially damaging to the environment.” RedViking has also seen a big increase in demand for powertrain test stands that use electrical energy regeneration, because they can recapture up to 80% of their power for reuse in testing.

Real efficiency opportunities

“A big part of improving energy efficiency for plant end users is getting rid of air-powered devices and machines,” notes RedViking’s Sobkow. “Air power is not an efficient means of transferring energy. Also, air systems frequently have leaks which create energy losses, are noisy and create condensation and mist that are unpleasant for the end users. Electronic drive methods for machines and tools eliminate these issues for end users in the factory.”

Efficient AGVs

“With the advent of assembly-line AGVs, conveyance is becoming a lot more energy-efficient,” says RedViking’s Sobkow. “Instead of running a giant chain-based conveyor that has to be built for maximum capacity, AGVs allow plants to buy only the conveyance they need for the current throughput. Inductively powered AGVs take this a step further by getting rid of batteries, charging stations and extra AGVs.

Architecting for energy efficiency

RedViking also does a lot with docking station architectures, with the core devices on the docking station and configurable wheeled fixtures moving in and out to accommodate different parts and processes, continues Sobkow. “In the past, you would have seen multiple machines, and you’re obviously expending more energy to run multiple machines,” he says. “But even in idle states you’re having parasitic energy loss from PLCs, operator displays, safety light screens and hydraulic pumps. When you put all of those energy-consuming elements on the docking stations and change function with swappable fixtures, you’re eliminating not only energy loss resulting from multiple active machines, you’re also eliminating that parasitic energy loss from supporting multiple machines in passive states.”

Capturing wasted energy

RedViking’s energy regenerating powertrain test stands have been a big energy saver. “Where old technology lost all expended energy in wasted heat, energy-regeneration technologies allow a dynamic component test stand to recover about 80% of its energy for reuse or, if their grid can accommodate it, returned to the energy source,” says Sobkow. Energy efficiency is a continuous part of RedViking’s process improvements. “We’re always looking for ways to increase flexibility to allow higher utilization rates of equipment, thus reducing idle-time power consumption,” notes Sobkow. “On a larger scale, we design and build machines and assembly lines to be flexible enough to incorporate future energy saving technologies.”

Sustainability as a way of doing business

At its most basic level, saving energy means saving money, says Sobkow. “At RedViking, sustainability is one of our core values,” he says. “We’re an ISO 14001 company, so we don’t just help our customers to be better environmental stewards; we’re taking that approach internally, as well.”